What is the optimal cycle time and temperature for sterilizing different types of medical instruments in a horizontal pressure steam sterilizer?

Posted by Admin | 23 Jul

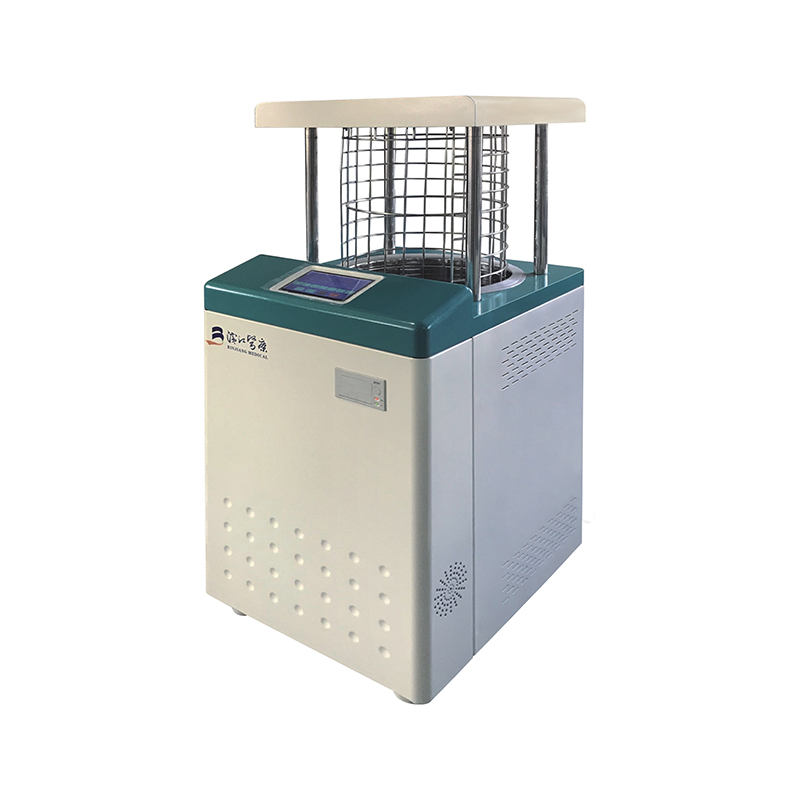

In the realm of medical and laboratory sterilization, the horizontal pressure steam sterilizer stands as a cornerstone of ensuring the safety and efficacy of reusable instruments and materials. Central to its operation is the precise control of temperature and cycle time, critical factors that directly impact the effectiveness of sterilization processes. These sterilizers utilize steam under pressure to eradicate microorganisms from surgical instruments, laboratory tools, and other medical equipment, thereby preventing the spread of infections and ensuring patient safety.

Temperature regulation is fundamental in steam sterilization, typically ranging between 121°C (250°F) and 134°C (273°F). The choice of temperature depends on the type of instruments and materials being sterilized. For instance, solid metal instruments can withstand higher temperatures, typically around 121°C, for a standard cycle duration of 15-20 minutes. This combination ensures thorough microbial destruction without compromising the integrity of the instruments. In contrast, porous materials like textiles or gauze require longer exposure times—often 30 to 60 minutes—to allow steam to penetrate deeply and eliminate microbes effectively.

The cycle time, alongside temperature, plays a crucial role in the sterilization process. It varies based on factors such as the sterilizer's design, load size, and the complexity of the items being sterilized. Modern horizontal pressure steam sterilizers often incorporate advanced features such as pre-vacuum pulses. These pulses help remove air from the chamber before introducing steam, enhancing the sterilization efficacy by ensuring steam penetration into intricate instrument channels or porous materials. This capability is particularly advantageous for sterilizing complex medical instruments like endoscopes, which demand meticulous cleaning and sterilization protocols to maintain patient safety.

Furthermore, the horizontal orientation of these sterilizers facilitates efficient loading and unloading of instruments, optimizing workflow in busy hospital environments and research laboratories. This design characteristic not only improves operational efficiency but also supports adherence to stringent sterilization protocols mandated by healthcare regulatory bodies worldwide.

In practice, healthcare facilities and laboratories adhere to validated sterilization protocols tailored to different types of instruments and materials. These protocols are designed to comply with regulatory standards such as those set by the FDA or CE marking, ensuring consistency and reliability in sterilization outcomes. The versatility of horizontal pressure steam sterilizers in accommodating various cycle parameters enables healthcare professionals to customize sterilization processes according to specific instrument requirements, thereby enhancing overall infection control measures.

In conclusion, the optimal cycle time and temperature for sterilizing different types of medical instruments in a horizontal pressure steam sterilizer are intricately linked to the materials being sterilized, their thermal tolerance, and the desired level of microbial elimination. By adhering to established guidelines and leveraging the advanced capabilities of modern sterilization technology, healthcare facilities can uphold the highest standards of patient care and laboratory safety, ensuring that every sterilized instrument meets rigorous hygiene standards before reuse in medical procedures or experimental research.

English

English русский

русский Français

Français Español

Español bahasa Indonesia

bahasa Indonesia Deutsch

Deutsch عربى

عربى 中文简体

中文简体