How does the gravity displacement method work in horizontal pressure sterilizers?

Posted by Admin | 15 Jul

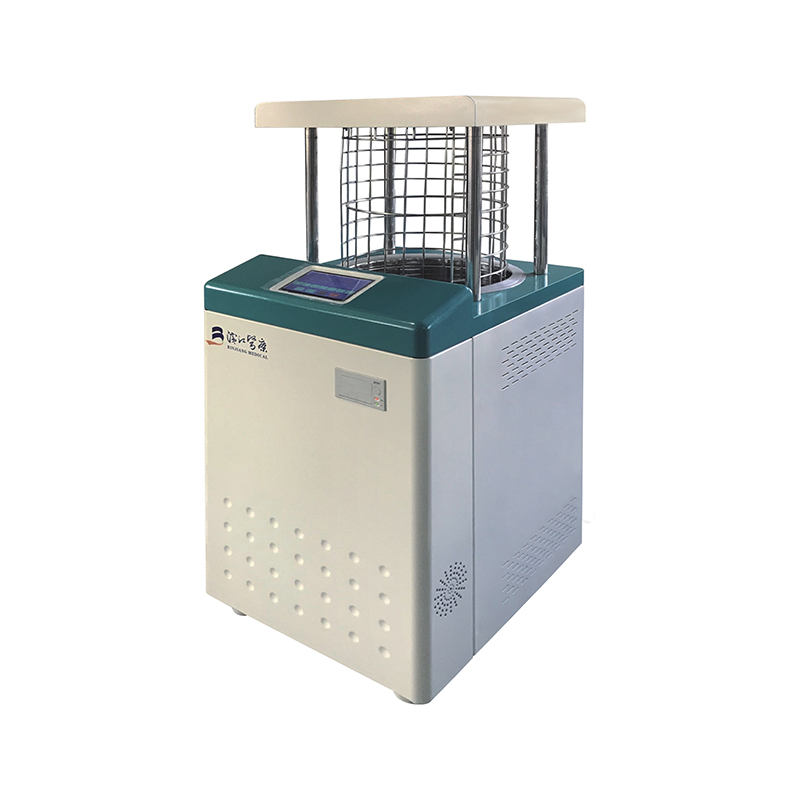

The gravity displacement method employed in horizontal pressure sterilizers is a pivotal mechanism for ensuring thorough and reliable sterilization of medical instruments, laboratory utensils, and other sensitive equipment. This method addresses the challenge of cold air within the sterilization chamber, which can compromise the effectiveness of the sterilization process.

At the outset of a sterilization cycle, the sterilizer creates a vacuum, effectively removing the majority of air from the chamber. This initial step significantly reduces the presence of cold air, which can harbor microorganisms and create uneven temperature distributions. Once the chamber is evacuated, steam is introduced. This steam displaces any residual air, penetrating all corners of the chamber and ensuring uniform exposure to sterilizing conditions.

The introduction of steam serves a dual purpose: it heats the chamber and its contents to the necessary sterilization temperature, typically around 121°C (250°F), and it condenses on cooler surfaces, effectively transferring heat and ensuring thorough sterilization. This process is particularly crucial in healthcare settings where complete elimination of pathogens is critical to preventing infections and ensuring patient safety.

Horizontal pressure sterilizers, leveraging the gravity displacement method, offer several advantages over other sterilization techniques. They are highly effective in achieving consistent sterilization results across a variety of loads and materials. This reliability is essential in environments such as hospitals, pharmaceutical facilities, and research laboratories, where strict adherence to sterilization protocols is mandatory.

Furthermore, these sterilizers are designed with user safety and operational efficiency in mind. By automating steam control based on chamber temperature, they optimize the use of resources while minimizing the risk of human error. This combination of precision and reliability makes horizontal pressure sterilizers indispensable tools in modern healthcare and scientific research, ensuring that instruments and equipment are reliably sterilized to the highest standards of safety and hygiene.

English

English русский

русский Français

Français Español

Español bahasa Indonesia

bahasa Indonesia Deutsch

Deutsch عربى

عربى 中文简体

中文简体