What types of materials and instruments are best suited for sterilization with a portable steam sterilizer?

Posted by Admin | 01 Aug

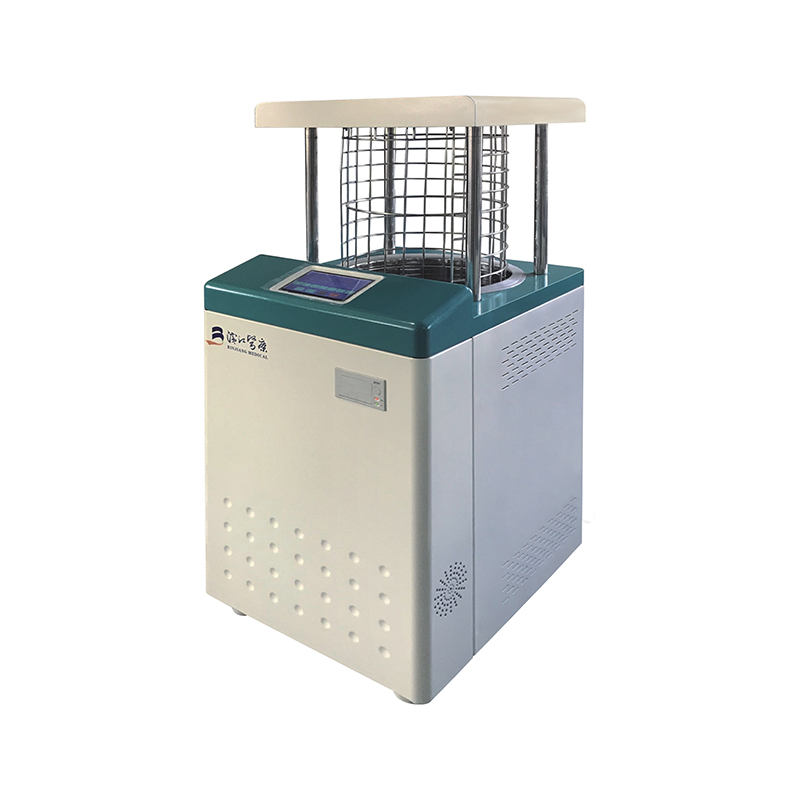

When considering the effectiveness of portable pressure steam sterilizers, it's essential to understand which materials and instruments are best suited for this method of sterilization. Portable steam sterilizers, also known as autoclaves, utilize high-pressure steam to achieve temperatures capable of destroying microorganisms, including bacteria, viruses, and fungi. This makes them a crucial tool in various settings, from medical facilities to laboratories and industrial environments.

The most suitable materials for steam sterilization are metals and certain heat-resistant plastics. Stainless steel surgical instruments, including scalpel blades, forceps, and scissors, are ideal candidates due to their ability to withstand high temperatures and pressures without degradation. Similarly, dental tools made from stainless steel are effectively sterilized in portable steam sterilizers. Laboratory glassware such as test tubes, beakers, and flasks, as well as medical glass bottles and jars, also fare well under steam sterilization due to their heat-resistant properties. Additionally, some ceramics, such as dental crowns, are heat-resistant and can be safely sterilized in a steam autoclave.

In terms of plastics, only those that are heat-resistant, such as some medical-grade polymers like polypropylene and polycarbonate, should be used in steam sterilization. These plastics can endure the high temperatures of steam without melting or deforming. Medical textiles, including surgical drapes and gowns, are commonly sterilized using portable steam sterilizers, provided they are made from materials that can tolerate high moisture and temperature conditions. Similarly, certain rubber items used in medical and laboratory settings, such as gaskets and tubing, are also suitable for steam sterilization if they are designed to withstand these conditions.

However, not all materials are suitable for steam sterilization. Heat-sensitive plastics, such as polyethylene and polystyrene, cannot endure the high temperatures and may deform or melt under steam conditions. Electrical components, which include various electronic sensors and machinery, should be avoided in steam sterilizers due to the risk of moisture damage. Corrosive metals, such as untreated iron or carbon steel, may also be unsuitable unless they are specially treated or coated to prevent rusting and corrosion. Additionally, wooden instruments are generally not recommended for steam sterilization as they can absorb moisture, leading to warping and deterioration.

The advantages of portable pressure steam sterilizers lie in their efficiency and effectiveness. By using high-pressure steam, these devices can achieve thorough sterilization quickly compared to other methods, ensuring that medical and laboratory equipment, as well as various industrial tools, are free of potentially harmful microorganisms. Their portability adds convenience, allowing for sterilization in different settings and locations where stationary units might not be feasible. This versatility and efficiency make portable steam sterilizers an indispensable asset in maintaining high standards of hygiene and safety across diverse applications.

Understanding the compatibility of materials with steam sterilization processes is crucial for optimizing the use of portable pressure steam sterilizers. By adhering to material guidelines and using appropriate sterilization practices, you can ensure that the items are effectively sterilized, thus enhancing safety and efficiency in various settings.

English

English русский

русский Français

Français Español

Español bahasa Indonesia

bahasa Indonesia Deutsch

Deutsch عربى

عربى 中文简体

中文简体