What maintenance procedures are required to ensure the proper functioning of a table-top steam sterilizer?

Posted by Admin | 19 Aug

Firstly, routine cleaning is essential to maintain optimal performance. After each use, it's important to clean the interior chamber of the sterilizer, removing any residues or contaminants. Use a soft cloth and a mild detergent to wipe down the chamber, ensuring that no abrasive materials are used that could damage the surfaces. Additionally, the door seals and gaskets should be inspected and cleaned regularly to prevent any buildup of residues that might compromise the seal and affect the sterilizer’s pressure and temperature control.

Secondly, the water used in the sterilizer plays a significant role in its maintenance. It’s crucial to use distilled or deionized water to prevent mineral deposits that can clog the steam lines and reduce the efficiency of the sterilization process. Regularly check the water level and top it up as needed, and ensure the water reservoir is cleaned periodically to remove any sediment or scale that may accumulate.

Regular inspection of the sterilizer’s filters is also necessary. Filters help to ensure that the steam produced is free from contaminants. These should be checked according to the manufacturer's recommendations and replaced when they become clogged or show signs of wear. Neglecting filter maintenance can lead to decreased performance and potential contamination of sterilized items.

The sterilizer’s safety features and indicators should be tested regularly to ensure they are functioning correctly. This includes checking the pressure gauges, temperature indicators, and automatic shut-off systems. These components are crucial for the safe operation of the sterilizer and must be calibrated according to the manufacturer's specifications to ensure accurate readings and effective sterilization cycles.

In addition to these routine procedures, it’s advisable to conduct periodic professional servicing of the sterilizer. This can help identify any potential issues before they become serious problems and ensure that the sterilizer remains in top working condition. Professional service typically includes a thorough inspection of all mechanical and electrical components, as well as any necessary repairs or adjustments.

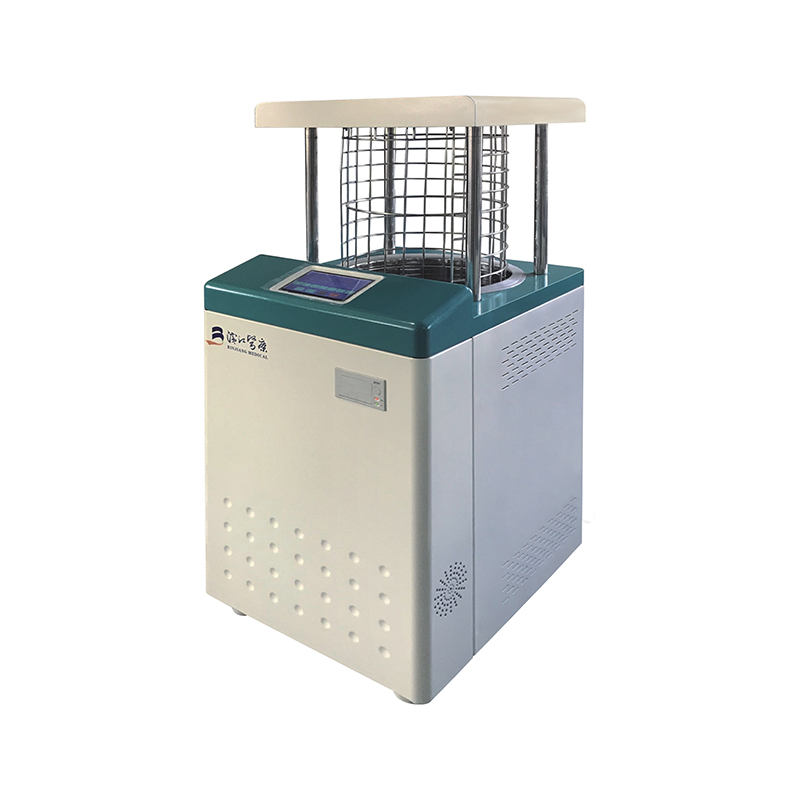

Our Table Top Steam Sterilizer excels in these maintenance aspects with its user-friendly design and high-quality construction. Designed to be both reliable and efficient, it simplifies routine maintenance with easy-to-access components and clear operational indicators. This not only ensures the long-term reliability of the sterilizer but also enhances the overall user experience by minimizing the time and effort required for upkeep. By following these maintenance procedures, users can ensure their table-top steam sterilizer continues to perform effectively, providing a critical tool for ensuring the safety and sterility of equipment and materials in a variety of professional settings.

English

English русский

русский Français

Français Español

Español bahasa Indonesia

bahasa Indonesia Deutsch

Deutsch عربى

عربى 中文简体

中文简体