What are the key differences between vertical and horizontal pressure steam sterilizers?

Posted by Admin | 14 Aug

When choosing a pressure steam sterilizer, understanding the differences between vertical and horizontal designs is crucial for selecting the right equipment for your needs. Both types of sterilizers serve the same fundamental purpose: using steam under pressure to eliminate microorganisms from instruments and materials. However, they differ significantly in design, operation, and application, which can impact their suitability depending on specific requirements.

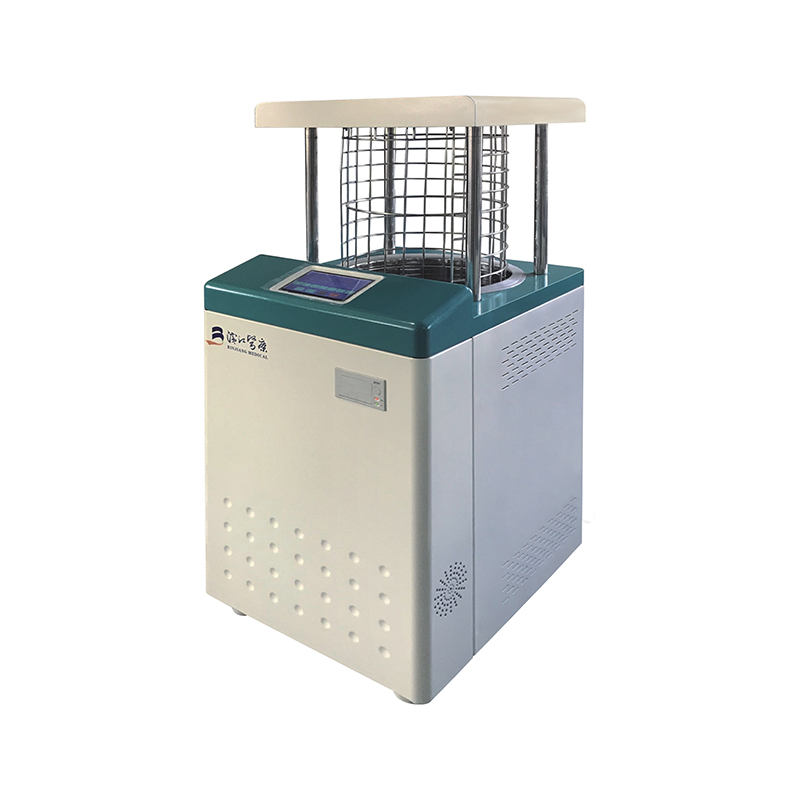

Vertical pressure steam sterilizers are characterized by their upright, cylindrical chambers. This design allows for efficient space utilization and makes loading and unloading more straightforward. Items are placed in the chamber either on shelves or within baskets, which are easily accessible from the top of the unit. The vertical orientation often means these sterilizers have a smaller footprint compared to their horizontal counterparts, making them ideal for environments where space is at a premium. Additionally, the vertical design supports gravity-assisted drainage, which can improve the effectiveness of steam penetration and condensation removal.

In contrast, horizontal pressure steam sterilizers feature a horizontally oriented chamber that opens from the front. This design typically supports larger capacities and is often used in settings where high volumes of items need to be sterilized simultaneously. The horizontal layout allows for easier loading and unloading of bulkier items or large quantities of smaller items. These sterilizers are generally favored in industrial or large-scale laboratory settings where space is less of a concern, but where operational efficiency and high throughput are critical.

One of the key differences between the two designs lies in their operational efficiency. Vertical sterilizers generally offer faster steam penetration due to the natural convection created by the vertical design. This can lead to more uniform sterilization and quicker cycle times, which is beneficial for environments where rapid turnaround is essential. The vertical pressure steam sterilizer's microcomputer control system further enhances this efficiency by precisely regulating temperature, pressure, and time, ensuring optimal sterilization conditions.

On the other hand, while horizontal sterilizers may require more time for steam to reach all areas due to their design, they often come with features tailored for high-volume processing, such as larger chamber sizes and automated loading systems. They are equipped to handle a significant number of items at once, making them suitable for large medical facilities or research laboratories.

Safety features are crucial in both types of sterilizers, with both vertical and horizontal models incorporating overheat and overpressure protection systems. However, the vertical sterilizer’s compact design often makes it easier to integrate these safety mechanisms effectively. Additionally, the vertical sterilizer's smaller size can lead to energy savings compared to larger horizontal units, as it typically requires less power to achieve and maintain the necessary sterilization conditions.

The choice between a vertical and horizontal pressure steam sterilizer depends on the specific needs of the user. The vertical pressure steam sterilizer offers advantages in terms of space efficiency, rapid steam penetration, and ease of use, making it particularly well-suited for environments where space is limited and quick turnaround is necessary. Its compact design and advanced microcomputer controls make it a reliable and cost-effective option for medical, research, and various other applications. Conversely, horizontal sterilizers cater to high-volume needs with their larger capacity and front-loading convenience, fitting better into settings where space is less of a concern but throughput is a priority. Understanding these differences ensures that users can select the sterilizer that best aligns with their operational requirements and space constraints.

English

English русский

русский Français

Français Español

Español bahasa Indonesia

bahasa Indonesia Deutsch

Deutsch عربى

عربى 中文简体

中文简体