What are the design features of modern table top steam sterilizers in terms of energy saving?

Posted by Admin | 04 Jul

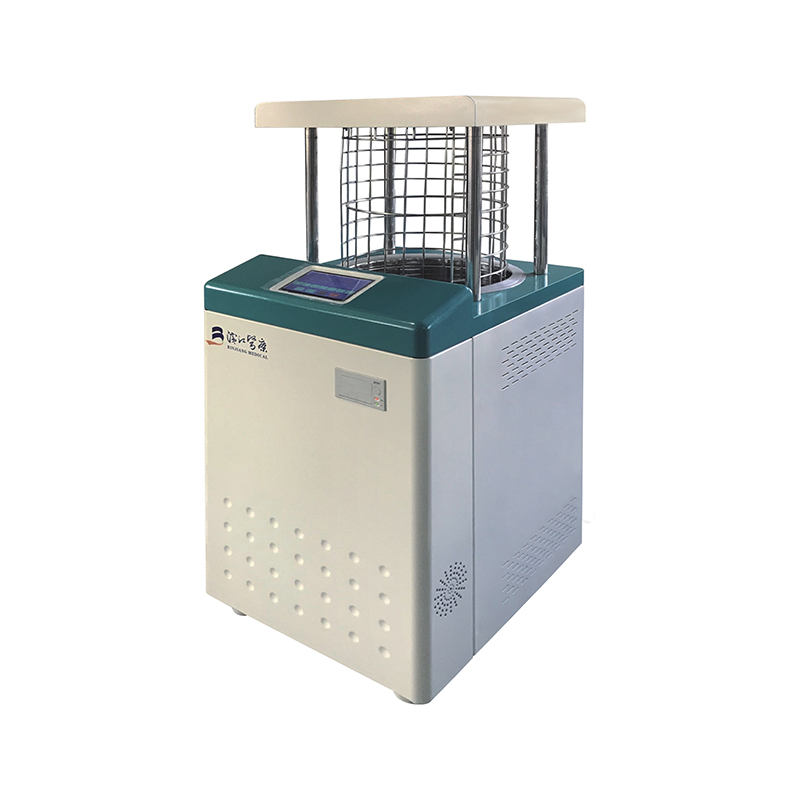

Modern tabletop steam sterilizers are designed with a range of energy-saving features to optimize energy consumption and reduce operating costs. Here are some of the main design features:

Efficient Steam Generator

Materials and Power: The steam generator is made of high-efficiency materials such as 316L stainless steel, capable of withstanding high power (e.g., 3 kW) and quickly producing ultra-pure steam. This material is not only durable but also enhances the purity and efficiency of steam production.

Heat Conversion Efficiency: With effective heat conversion design, the steam generator maximizes energy use and minimizes heat loss, thereby increasing overall energy efficiency.

Intelligent Control System

Precise Control: Equipped with a highly accurate control system, it can precisely regulate parameters like temperature and pressure during the sterilization process, ensuring effective sterilization while avoiding energy wastage. For example, the temperature can be controlled within a ±0.5℃ range.

Automatic Programs: The system offers multiple preset and customizable programs, allowing users to choose appropriate sterilization programs based on actual needs, optimizing energy consumption. The intelligent control system can also automatically adjust operating modes according to the load, achieving the best energy-saving effect.

Energy-Efficient Cooling System

Efficient Vacuum Pump: Featuring an efficient diaphragm vacuum pump, it rapidly cools the gases extracted from the chamber through an air heat exchanger, ensuring high-efficiency operation of the vacuum pump without needing external water connections for cooling. This design not only saves water resources but also reduces energy consumption during the cooling process.

Multiple Pre-Vacuum and Post-Vacuum Drying Functions: The system provides multiple pre-vacuum and post-vacuum drying functions to effectively remove air and moisture from the chamber, improving sterilization efficiency and reducing energy waste.

Energy-Saving Materials and Structural Design

High-Quality Materials: The chamber is made of 316L special stainless steel with strong corrosion resistance, ensuring that long-term use will not decrease energy efficiency due to corrosion. Additionally, the entire chamber is electroplated, further enhancing durability and cleanliness.

Insulation Design: Components such as the door handle are made from heat-insulating materials like hard plastic to ensure that no heat is lost during operation.

Energy-Saving and Environmentally Friendly Additional Features

Water Shortage Protection Reminder: Equipped with a water shortage protection probe, it automatically alerts for water addition, preventing the device from operating in a water-deficient state, which could cause damage or increase energy consumption.

Real-Time Monitoring and Recording: The system features real-time monitoring, which can transmit or save sterilization records, making it easier for users to analyze device performance and optimize sterilization programs for further energy savings.

Modern tabletop steam sterilizers achieve energy conservation and emissions reduction through efficient steam generators, intelligent control systems, energy-efficient cooling systems, energy-saving materials and structural designs, and environmentally friendly additional features. These designs not only improve the energy efficiency ratio of the equipment but also reduce operating costs, meeting the energy-saving and environmental requirements of modern medical institutions and laboratories.

English

English русский

русский Français

Français Español

Español bahasa Indonesia

bahasa Indonesia Deutsch

Deutsch عربى

عربى 中文简体

中文简体