How does the micro-computer controlled system enhance sterilization efficiency?

Posted by Admin | 23 Sep

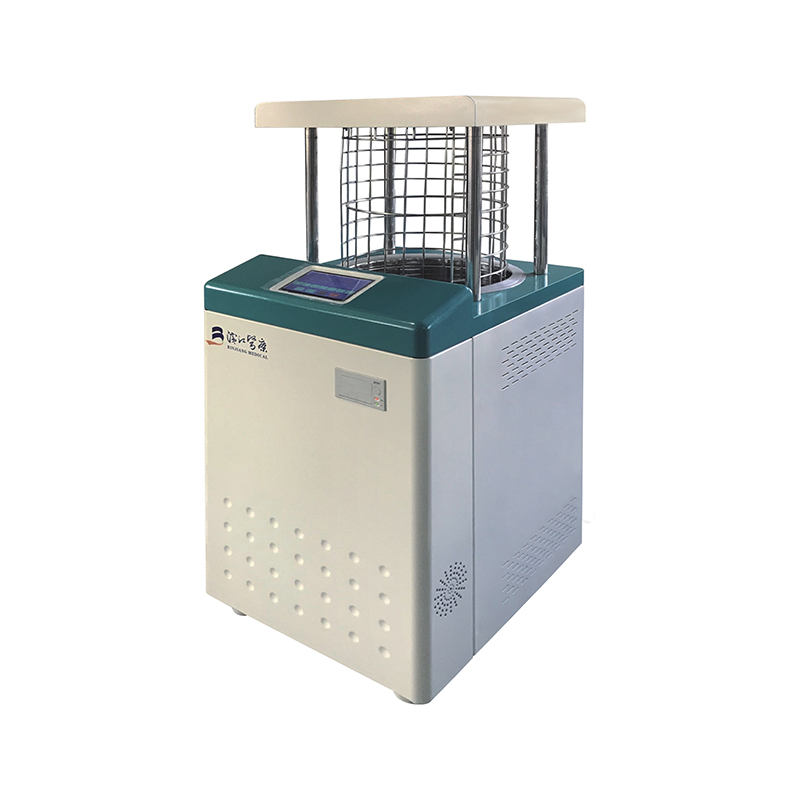

The Fully Automatic Circulation Vertical Pressure Steam Sterilizer represents a significant advancement in sterilization technology, primarily due to its micro-computer controlled system. This sophisticated system is central to enhancing sterilization efficiency and reliability, making it an invaluable tool in medical, research, and industrial settings.

At the heart of the micro-computer controlled system is its ability to precisely regulate and monitor the sterilization process. By continuously tracking key variables such as temperature, pressure, and time, the system ensures that these parameters remain within the optimal range for effective sterilization. This precision is crucial because even slight deviations from the required conditions can compromise the sterilization process, leading to ineffective treatment of equipment and materials. The micro-computer's real-time adjustments and monitoring help maintain consistent conditions throughout the cycle, thereby improving the overall effectiveness of the sterilization.

Another significant advantage of this system is its automation capabilities. Traditional sterilization methods often require manual adjustments and constant supervision, which can introduce human error and variability. The micro-computer controlled system automates these adjustments, reducing the risk of human error and ensuring that each sterilization cycle adheres to the predefined protocols. This automation not only enhances reliability but also streamlines operations, allowing personnel to focus on other tasks while the sterilizer handles the process independently.

Energy efficiency is another benefit provided by the micro-computer controlled system. By optimizing the heating and pressure cycles based on real-time data, the system minimizes energy consumption while still achieving thorough sterilization. This not only reduces operational costs but also contributes to more sustainable practices by decreasing overall energy usage.

In addition to improving efficiency, the micro-computer controlled system incorporates advanced safety features. It includes overheat and overpressure protection mechanisms that automatically regulate and correct any deviations from safe operating conditions. This not only ensures the safety of the equipment and personnel but also prevents potential damage to the sterilized items, maintaining the integrity of both the sterilizer and the materials being treated.

Historically, sterilization technology has evolved significantly, moving from manual and less precise methods to these highly automated and reliable systems. The development of micro-computer controls marks a notable leap forward, reflecting broader trends in technology that emphasize precision, efficiency, and safety. As sterilization practices continue to advance, the integration of sophisticated controls like those in the Fully Automatic Circulation Vertical Pressure Steam Sterilizer underscores the ongoing commitment to enhancing the effectiveness and reliability of critical sterilization processes.

English

English русский

русский Français

Français Español

Español bahasa Indonesia

bahasa Indonesia Deutsch

Deutsch عربى

عربى 中文简体

中文简体