Ensuring Effective Sterilization for Diverse Items in a Horizontal Pressure Sterilizer

Posted by Admin | 25 Nov

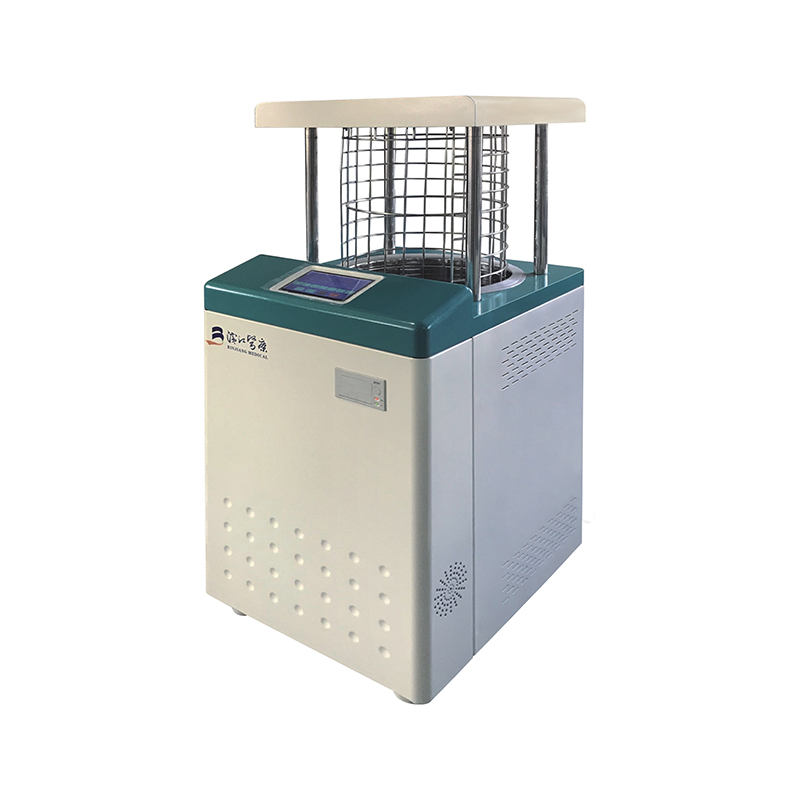

Table Top Pulse Vacuum Steam Sterilizers, which use the gravity displacement method, have proven to be reliable and versatile in accommodating a wide range of items, from delicate glassware to heavy surgical instruments. However, a common question that arises is whether these sterilizers can handle such diversity without compromising the quality of sterilization. The answer lies in the design, functionality, and careful usage of these machines.

Horizontal pressure sterilizers are designed to offer uniform sterilization by utilizing steam under pressure, which penetrates into the items being sterilized. The advantage of the gravity displacement method is that it allows for even steam distribution throughout the chamber, ensuring that all items—regardless of their shape, size, or material—are exposed to the sterilizing steam. This is particularly important in settings like hospitals, pharmaceutical factories, or scientific laboratories where the sterilization of both complex and simple items is necessary. These sterilizers can handle a variety of instruments, from small glass vials to larger, irregularly shaped surgical tools, by ensuring that steam circulates evenly and effectively.

One of the key considerations when loading a horizontal pressure sterilizer is the arrangement of the items within the chamber. Proper placement allows for optimal steam penetration, ensuring that all surfaces of the items are exposed to the steam. Even when items come in different shapes—such as tubes, jars, and surgical instruments—proper positioning ensures that sterilization is not hindered. It is also critical to avoid overcrowding, as this can restrict steam flow and affect the sterilization process. By following proper loading protocols, sterilizers can maintain their high standards of sterilization even for diverse items.

Moreover, these sterilizers are equipped with advanced control systems that regulate temperature, pressure, and sterilization time, ensuring that the sterilization process is precise and effective. For more delicate items like glassware, which could be more susceptible to breakage, the system can be adjusted to ensure a gentler, slower process without compromising the quality of sterilization. This adaptability ensures that no matter the material or configuration of the items being sterilized, they receive the same level of thoroughness.

In terms of maintaining the quality of sterilization, horizontal pressure sterilizers are built to meet stringent standards, ensuring that no matter the type of material—metal, plastic, or glass—the sterilization process is completed effectively. Whether sterilizing surgical instruments, laboratory glassware, or other medical equipment, these sterilizers can be relied upon to deliver consistent results that meet the highest safety and hygiene standards. The versatility and precision offered by these machines allow them to adapt to different sterilization needs, providing peace of mind that items of varying shapes and sizes will be properly sterilized without compromising on quality.

A well-maintained Table Top Pulse Vacuum Steam Sterilizer using the gravity displacement method can handle items of all shapes and sizes with exceptional efficiency. Whether it’s delicate glassware or larger, complex surgical instruments, these sterilizers are designed to ensure that every item receives thorough and consistent sterilization, maintaining the integrity of both the process and the materials. Proper loading, along with adjustable settings, allows for the versatility needed to sterilize a diverse range of items without compromising on quality, making them indispensable in fields that require the highest standards of cleanliness and safety.

English

English русский

русский Français

Français Español

Español bahasa Indonesia

bahasa Indonesia Deutsch

Deutsch عربى

عربى 中文简体

中文简体