From precision engineering to impeccable service, JIBIMED sets the standard for medical sterilizers. Join the ranks of satisfied customers worldwide.

-

Hospital

-

Laboratory

-

Pharmacy

-

Food & Beverage

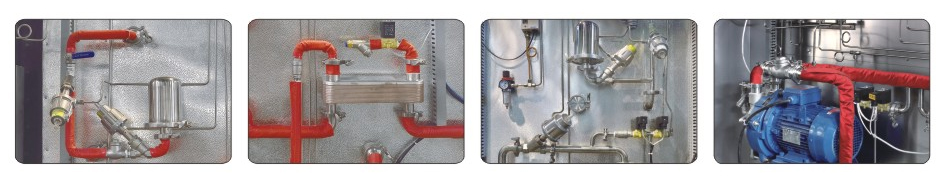

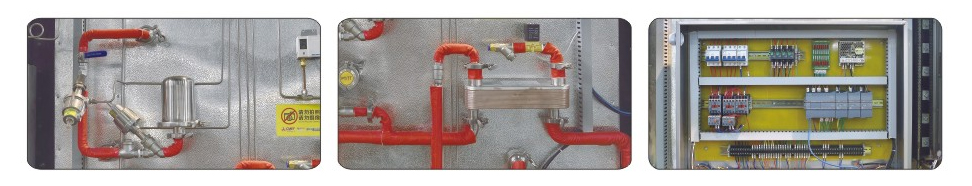

WG series pulsating vacuum sterilizers use saturated steam as the sterilizing medium, by relying on the physical property that the saturated steam can release a large amount of latent heat and moisture during condensation, it renders items to be sterilized in a highly heated and humid state. After a period of heat preservation, the purpose of sterilization is achieved. The effect of cold air on temperature is eliminated by means of pulsating vacuum exhaust, finally, the items drying is realized by vacuum dehumidification combined with a jacket. WG series pulsating vacuum sterilizers are mainly used in central sterile supply departments, third-party disinfecting supply centers, and operating rooms, where medical devices, dressings, rubber, lumen devices, implantable devices, and liquids are sterilized.

WG series pulsating vacuum sterilizer uses saturated steam as the sterilization medium, which would completely penetrate into the surface of the articles through a pulsating vacuum, and all the microorganisms and their spores would be killed by it under high pressure. It is reliable and effective method of physical sterilization. Pulsating vacuum exhaust eliminates the influence of cold air on temperature, finally, the sterilizing articles are dried by vacuum dehumidification combined with a jacket. WG series pulsating vacuum sterilizer can be widely used in pharmaceutical, bioengineering, medical health, scientific research, and other fields. It is applied to sterilizing articles with high-grade requirements, such as sterile clothes, medical cages, tools, instruments, rubber, liquid, medical dressing, and so on.

Suitable for hospital surgical knives, hemostatic forceps, tweezers, dressing bowls, various trays, and cylindrical containers. When used with different cleaning racks or procedures, it can also be used to clean respiratory tubes, anesthesia tubes, minimally invasive instruments, plastic products, and various medical devices. It can provide standardized and automated cleaning treatment for the majority of reusable medical instruments, effectively preventing cross-infection.

The vertical pressure steam sterilizers are assembled with a heating system, micro-computer controlled system, and overheat and overpressure protection system, which are reliable for the sterilizing effects, convenience of operation, and energy conservation. They are suitable for sterilizing equipment, dressings, containers, liquids, culture medium, waste, etc. in hospitals, disease control centers, P2 biological laboratories and blood stations, etc. of scientific research institutes.

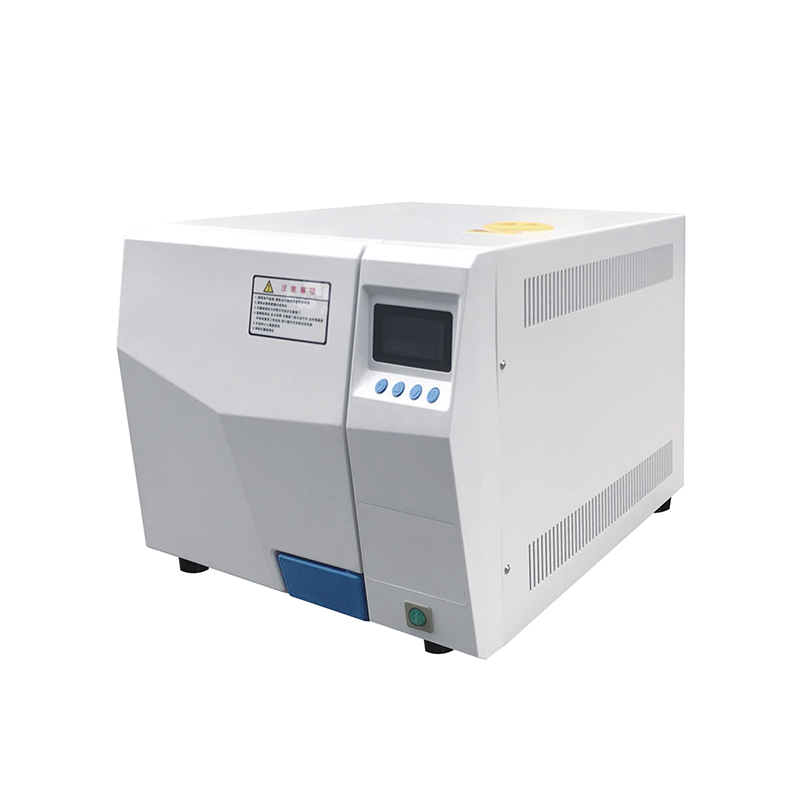

LCD display automation Vertical Pressure Steam Sterilizer is a Fully stainless steel structure, This feature ensures durability, corrosion resistance, and easy cleaning of the sterilizer. Stainless steel is commonly used in medical equipment due to its hygienic properties. Auto discharge the cool air, and steam, Hand wheel type of quick- -open door, With two stainless steel sterilizing baskets. enhances the efficiency of the sterilization process and ensures a safe and controlled environment when opening the sterilizer after the cycle. The LCD display provides a visual representation of the sterilizer's current status. It displays information such as temperature, pressure, and cycle progress, allowing users to monitor the sterilization process in real time.

The ophthalmic instrument used Table Top Steam Sterilizer for Rapid sterilization in 4~6 minutes, a quick sterilization cycle, which is essential for the efficient processing of ophthalmic instruments. the sterilizer is equipped with safety measures to prevent operation when there is a lack of water, protecting the equipment and ensuring the effectiveness of sterilization. offers flexibility with both pre-set sterilization programs and the ability for users to adjust settings based on their specific needs. The whole process of water adding, temperature rising, sterilizing, drying, and steam discharging is controlled automatically: This indicates a fully automated sterilization process, minimizing the need for manual intervention. With four stainless steel sterilizing plates: The sterilizer includes stainless steel plates for placing ophthalmic instruments during sterilization.

The series of water bath sterilizers utilize high-temperature circulating water as the sterilization medium. The items undergo a process of spray heating, sterilization, and cooling, keeping them in a high-temperature and humid state. Through a period of incubation, the desired sterilization is achieved. The sterilization medium circulates within a sealed space, effectively preventing secondary contamination. The sterilization process includes counter-pressure to avoid bottle or bag rupture. This equipment has a wide temperature control range and great temperature uniformity.

It is suitable for sterilizing various moisture-resistant glass bottles, plastic bottles, and flexible bag-packaged liquid products in industries such as pharmaceuticals.

These sterilizers use high-temperature deionized water as the sterilization medium. The deionized water circulates internally and uniformly sprays onto the sterilized items for a certain period of time to achieve sterilization. They have a wide temperature control range and great temperature uniformity, while avoiding secondary contamination during operation. They are equipped with a leak detection method combining vacuum and color water.

These sterilizers are suitable for industries such as pharmaceuticals, medical, and scientific research. They are designed for high-temperature sterilization, leak testing, and cleaning of ampoules, vials, and other injectable and oral liquid products.

This series of Chinese medicine sterilizers utilize saturated steam as the sterilization medium. The physical characteristic of releasing a large amount of latent heat upon condensation is utilized for sterilization. By taking advantage of the strong penetration of steam and maintaining a certain temperature for a period of time, sterilization is achieved. The sterilizer can be equipped with a coil drying system to prevent powder agglomeration and achieve effective drying.

It is suitable for sterilization and drying of spices, traditional Chinese medicine powders, medicinal herbs, and similar substances.

These sterilizers use high-temperature deionized water as the sterilization medium. The deionized water circulates internally and uniformly sprays onto the sterilized items for a certain period of time to achieve sterilization. They have a wide temperature control range and great temperature uniformity, while avoiding secondary contamination during operation. They are equipped with a leak detection method combining vacuum and color water.

These sterilizers are suitable for industries such as pharmaceuticals, medical, and scientific research. They are designed for high-temperature sterilization, leak testing, and cleaning of ampoules, vials, and other injectable and oral liquid products.

LCD display automation Vertical Pressure Steam Sterilizer is a Fully stainless steel structure, This feature ensures durability, corrosion resistance, and easy cleaning of the sterilizer. Stainless steel is commonly used in medical equipment due to its hygienic properties. Auto discharge the cool air, and steam, Hand wheel type of quick- -open door, With two stainless steel sterilizing baskets. enhances the efficiency of the sterilization process and ensures a safe and controlled environment when opening the sterilizer after the cycle. The LCD display provides a visual representation of the sterilizer's current status. It displays information such as temperature, pressure, and cycle progress, allowing users to monitor the sterilization process in real time.

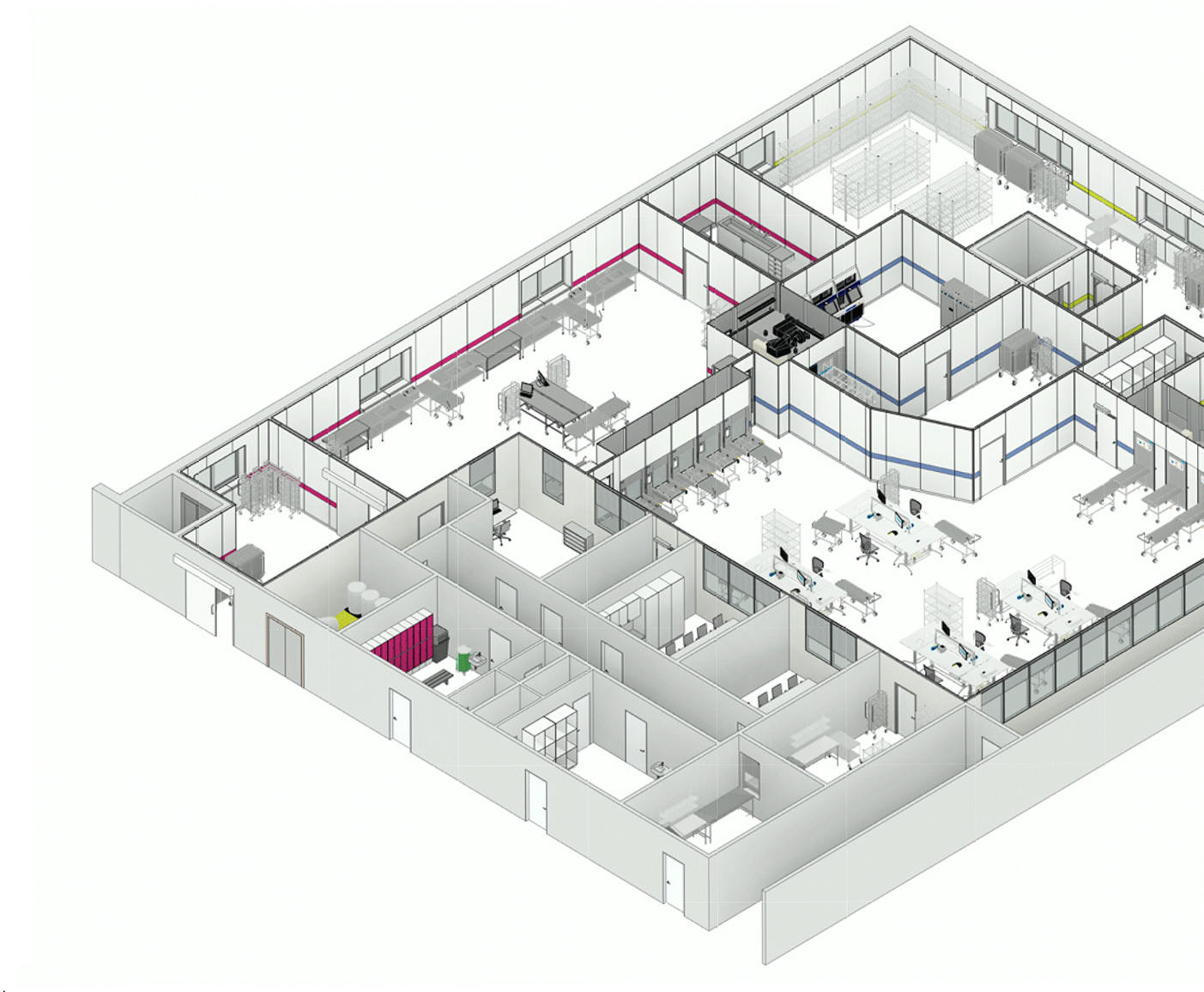

The CSSD Retrieve System is a valuable tool for enhancing operational efficiency

-

SterilizeSupport the empty sterilizing and daily sterilizing (high temperature or low temperature), real-time recording the sterilizing time, sterilizing staff, and the instrument packages. Provide the sterilizer statue inquiry (spare time, sterilizing standby, in sterilization), as well as displaying the detailed items information and the total amount.

-

StorageSupport the empty sterilizing and the daily sterilization, real time recording the sterilizing time, sterilizing staff and the instrument packages. Provide the statues inquiry, display the detailed items information and the total amount.

-

DistributionSupport the application of the distribution of the disposable items. Support the application of the distribution of the non-disposable items. Distribution application, lend distribution, partialitems distribution. Support the distribution of the self-prepared items. Support the distribution of the surgical instruments

-

RetrievalDisposable ltems Retrieval

Retrieve the distribution of the disposable items and the related historical info, and proceed with the statistics inquiry according to the producing batch number.

Non-disposable ltems Retrieval

Fully trace all information throughout the process of device recycling, cleaning and disinfection, packaging, sterilization, distribution, and utilization. Tracing the department where the items cleaned in the same batch are located.Tracing the department where the items sterilized in the same batch are located -

RecyclingSupport the manual recycling: input the recycling department the items.

Support centralized recycling: automatically retrieve all departmental application forms.

Detailed record the recycling staff, time, recycling department and the items quantity. Recycling inquiry. -

CleaningRecord the entire process of the washing disinfector.

Cleaning procedure, staff, cleaning batch, the start and the end time.

Support the record of the manual cleaning process, including clean staff and time.

Check the cleanliness status and tray status, as well as the verification. -

PackageSupport printing the barcode label on the washed items.

Support printing the barcode label on the dressing items.

Support printing the barcode label on the normal monitoring packages.Barcode identification of the package, including items name and specification, package staff, sterilizing mode, sterilizing date, expiration date, record print staff, packaging date.

Empowering healthcare providers worldwide

-

R&D

Our research and development team consists of highly qualified professionals, including foreign expe...

-

High Quality

We adhere to the principles of "high quality, high standards, and cost-effectiveness" and strive to ...

-

Innovation

With a strong R&D team and great designers, Binjiang Medical understands that innovation is the ...

-

2026-01-19

Hydrogen Peroxide Plasma Sterilization: Principle, Pros & Limits

Hydrogen peroxide low-temperature plasma sterilization is a fast, low-heat method for heat- and moisture-sensitive medical instruments, but it has strict limitations on lumen geometry, material compat... -

2026-01-19

Why Steam Autoclave Sterilization Fails: Fast Root-Cause Checklist

High-pressure steam sterilization failures are most often caused by incorrect cycle settings, poor air removal, improper loading/packaging, or equipment/steam-quality issues. A structured check—starti... -

2026-01-16

How Must an Autoclave Be Loaded? Practical Loading Rules

How must an autoclave be loaded? Load it so steam can contact every surface: use trays/racks, keep items off chamber walls, avoid stacking, separate packages, place heavier/rigid items below lighter/w...

English

English русский

русский Français

Français Español

Español bahasa Indonesia

bahasa Indonesia Deutsch

Deutsch عربى

عربى 中文简体

中文简体